Are you bored of board, card or paper - items all purchased easily from art supply stores or high street printers? Do you sit at your desk designing and dreaming about printing to something a bit more interesting, a bit more off the wall? Well, today's your lucky day!

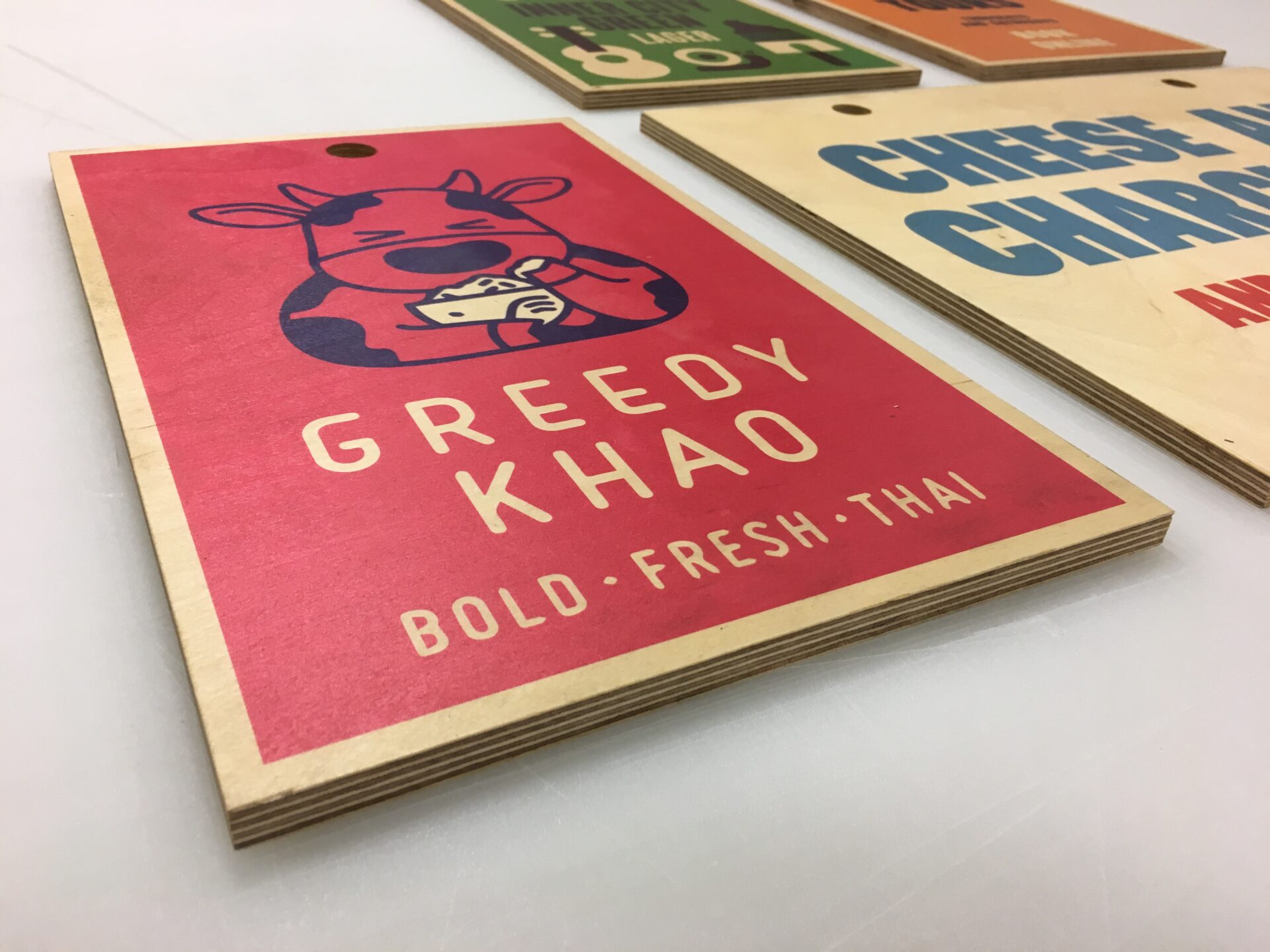

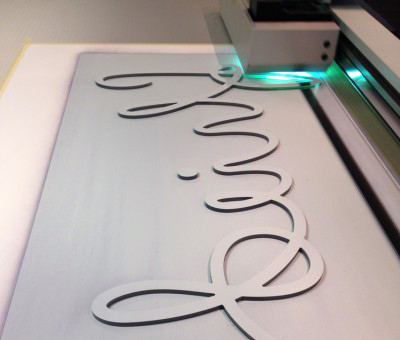

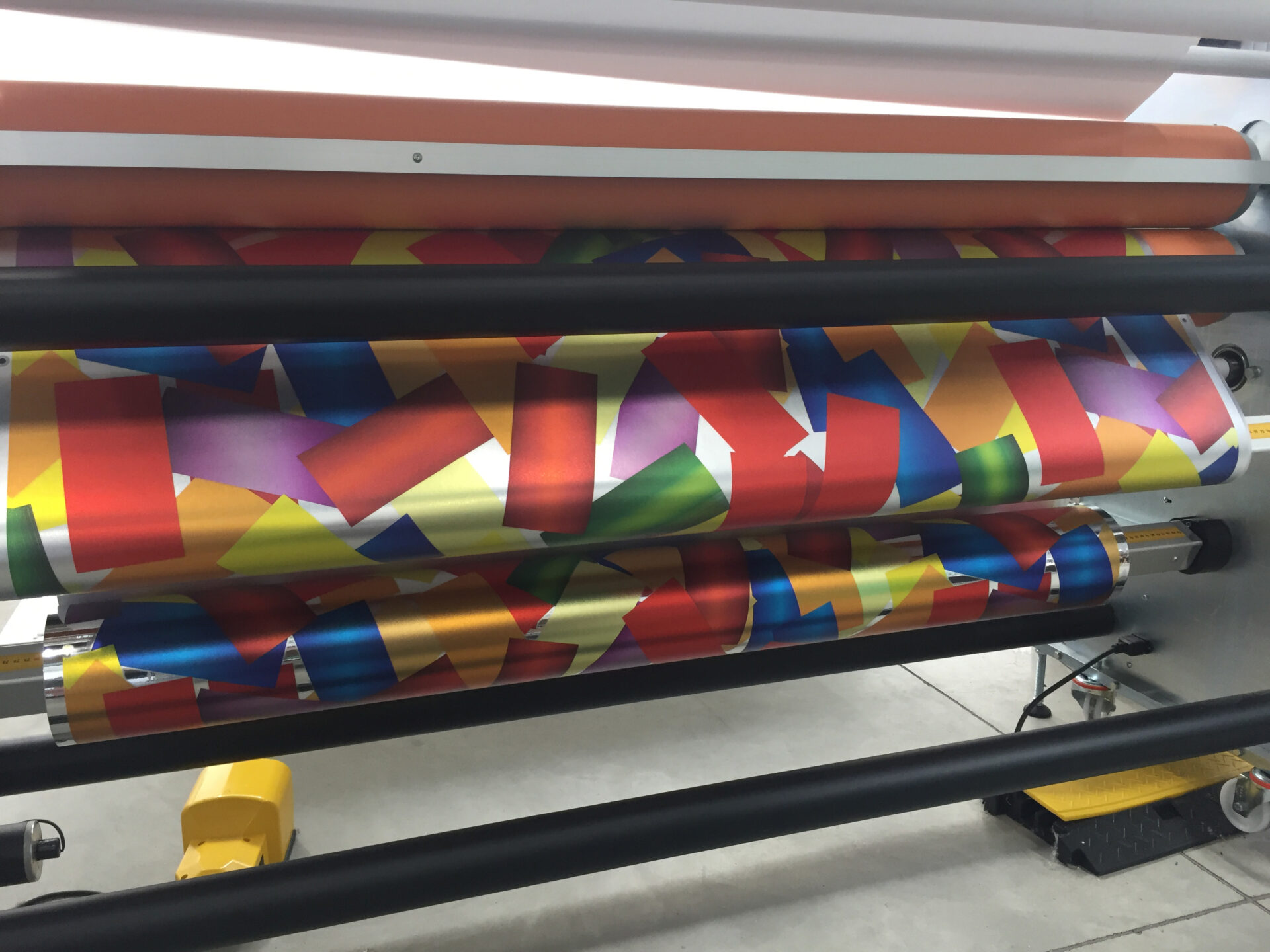

Direct to media printing, or DTM, is when we print directly to the surface of a substrate including various rigid and exible media. So, as we suggested, apart from the usual suspects of foamboard, cardboard or paper how about opening up your horizons to print on a variety of different materials. Our printers can produce brilliant, vibrant designs to wood including MDF, plywood, doors, tabletops etc.; Or how about metal including aluminium, tin, iron; Plastics? Acrylics? Dibond? Floor tiles, even ceramic tiles? Correx? Corrugated board? If it fits under the 50mm print heads, in theory, we can print onto it - we welcome all ideas, no matter how unusual sounding. The technology is a flatbed inkjet printer, so the material is fed through the ink heads either as a sheet or as a roll. And as well as the possibility of printing the flat substrates we also have specially prepared materials like cloth, canvas, mesh and cotton as well as clear stocks including static or adhesive films.

You might be thinking “how do we print to a coloured material?†Well, using white ink allows us to print solid colours onto non-white substrates, clear films and boards. First, we print a layer of white ink before overlaying with colour. Do you remember the fluorescent graphics we produced for our own exhibition stand at the VM Show in 2018? It was printed using this exact method. And there's always the range of metallic vinyl you could use including gloss, mirrored or matte silver and gold, or bronze and copper.

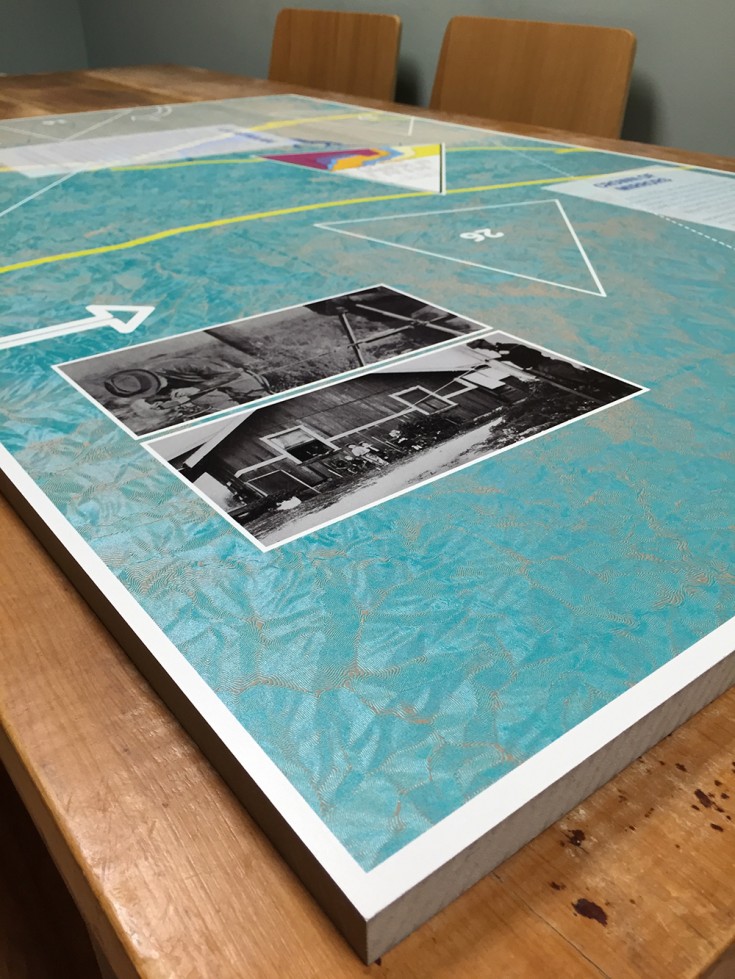

Depending on the material texture, you should be able to see the depth and personality of the substrate used with your design printed to its surface. Another trick we can use with the Direct to Media technology is to create our own texture to a material. This can be done by printing multiple layers of ink, as in the examples below.

We've produced DTM for all manner of briefs including point of sale, office interiors, signage, art, furniture, exhibition panels, stage graphics. backdrops and building site hoardings.

We love a challenge so make sure you get in touch to ask us how we can help you get your messages directly onto a wide range of media. Remember, as long as the material fits under the 50mm ink heads, let your imagination go wild or ask us for our thoughts and advice.