The Graphical Tree loves a challenge (honestly we do). So when we were asked by our friends at Rococo Chocolates to create a bespoke printed free-standing 3D display that had functional shelf sections to place items on for their store in Mayfair, we got stuck in.

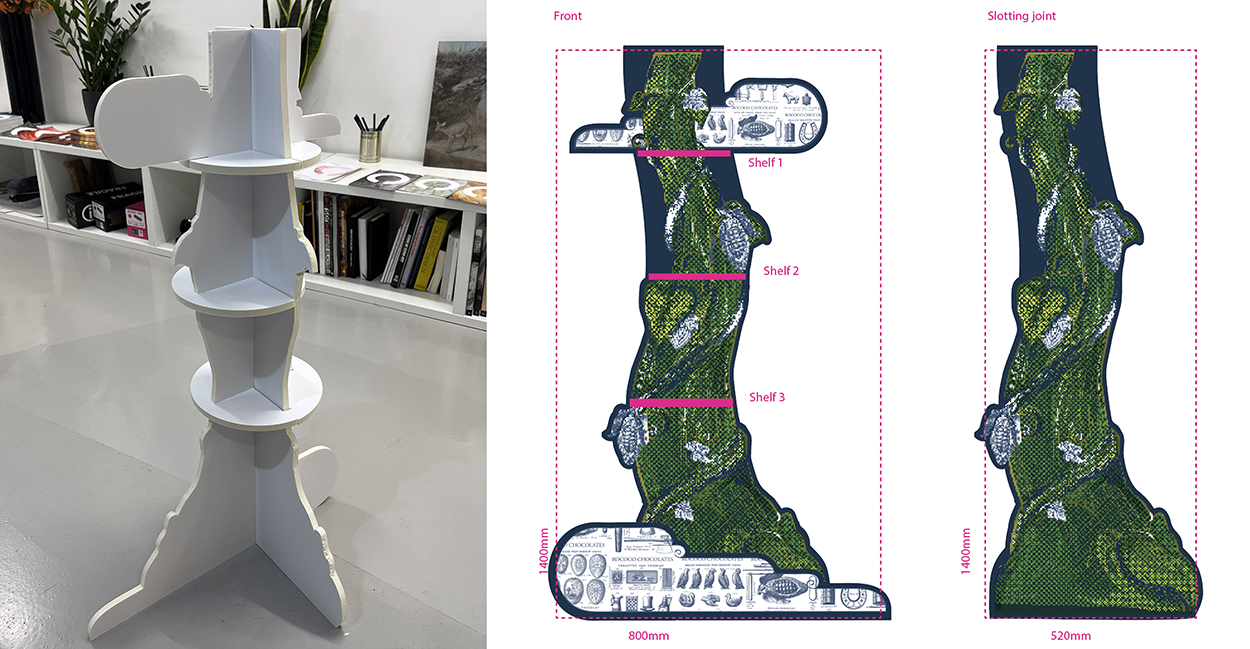

To start off the process, and offer up some visual inspiration, Rococo supplied a company-branded beanstalk illustration. We set about working out how to apply this and construct it into a three-dimensional functional piece of P.O.S. (Point of Sale). Our first idea was to draw the exterior path around the beanstalk and theorize interlocking central channels to form an exploratory two-piece free-standing unit. Bingo, it worked first time, hardly genius, but experience counts and it gives you a platform to use when working out something new.

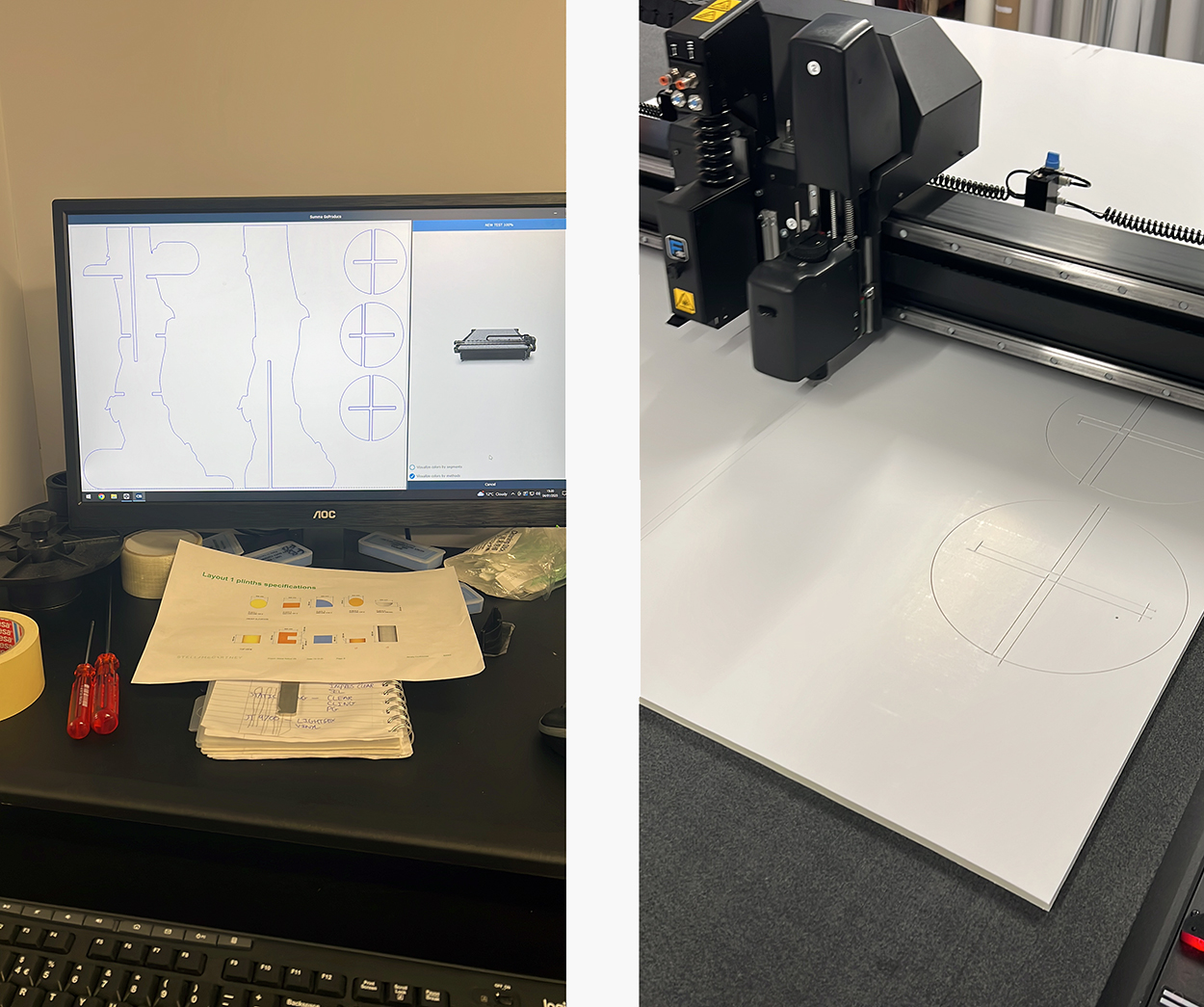

The next challenge was to understand how to add shelving sections. How large should these be, what shape, and what thickness board was needed? If you don't try, you don't know. First off we set about producing a variety of possible shapes and board widths to test for strength and viability. After some shape play, we settled on shelves modeled as semi-circles that pushed together to form a seamless full circle once locked in together. These fitted into notches constructed within the main stalk section. Tests were run at half-size using a number of possible boards. These included a 5mm foamboard to ensure all the pieces fitted and locked into place successfully. Due to the irregular shape of the beanstalk, the shelf sections had to be trimmed by hand to fit seamlessly together.

Taking the time for product development very often pays dividends. And being willing to trial different substrates allowed us to see which would be the most durable and practical with which to build the end product.

The final unit was direct-to-media printed double-sided on 16mm Dufaylite (an eco honeycomb paper-based board) cut to shape and then finished by hand to form the unit. As a result of our successful R&D, the shelves were strong enough to hold anything we put on them, making them more than suitable for Rococo's delicious chocolates.

Here's more of our retail work, and please drop us a line if you'd like to talk to us about your own projects. Email us: print@thegraphicaltree.com