Eco-solvent printing is a method of digital printing that uses eco-solvent inks to produce high-quality prints. The ink is applied to the printing substrate – such as vinyl or canvas – using a printer equipped with eco-solvent cartridges. These contain pigments or dyes that are dissolved in a mild solvent, resulting in reduced emissions of harmful fumes during the printing process.

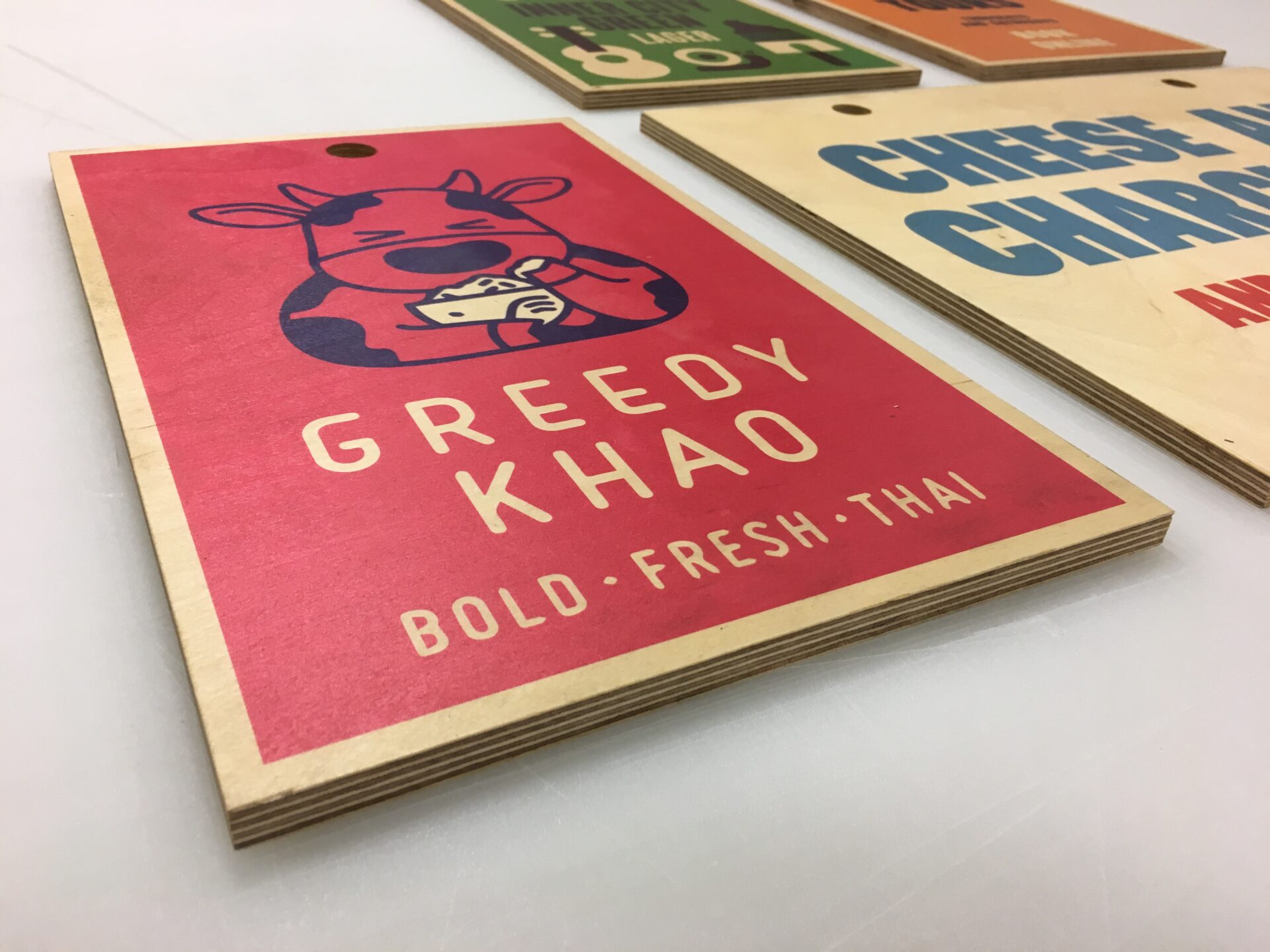

The eco-solvent printing process offers several advantages. The inks involved have a substantially reduced impact on the environment due to having a lower volatile organic compound (VOC) content, heavy metals, SVHCs or greenhouse gases – making them more sustainable compared to traditional solvents. It also offers excellent colour reproduction and vibrancy – producing high-quality prints with sharp details and vivid hues. This method can also be used on a wide range of substrates – including those that are sensitive to heat, meaning that it's suitable for a variety of applications such as outdoor signage, banners, or indoor displays.

Eco-solvent inks are full waterproof, once dry. Furthermore, they are very resistant to fading and weathering, making them suitable for long-term outdoor applications without the need for additional lamination or protective coatings.

The term solvent is used to describe any ink that is not water-based. Usually, it is those whose inks use petroleum or a petroleum by-product for their ink. Solvent prints are waterproof and can be used to print directly onto media such as vinyl and rigid substrates like painted or coated metal, foamboard and PVC based boards.

The solvents soften the base material and allow the ink pigments to latch to the chemically etched surface. This is what makes solvent ink prints more durable than aqueous (water-based) inks.

However, solvent inks give off a strong odour or fumes when drying, therefore releasing hazardous air pollutants (HAPs) as the carrier fluid dissipates into the surroundings through the heat applied from the printer. These would affect both the production environment and the end destination for the graphics.

But the good news is, our direct-to-media printers ticks as many boxes as we can for eco-printing. The ink used has been given the environmentally friendly Gold Award from GREENGUARD. It has a less harmful chemical makeup than many other printers in circulation and includes up to 50% naturally-derived monomers and oligomers from renewable resources, such as plants or biomass. Eco-solvent inks usually contain glycol esters or glycol ether esters instead. And while they are usually slower drying, our eco-solvent UV printers use a LED lamp system, called “cool cureâ€, for faster drying the ink, instead of mercury-based cooling. This means we are using up to 82% less energy consumption than other non-comparable UV machines might.

As the manufacturer for our direct-to-media, we've been told that “no other technology in its class can deliver the environmental benefits to satisfy demands for a greener printing solution with less waste, fewer consumables and decreased power consumption.†It all helps bring us closer to achieving our eco print and production goals and a smaller environmental footprint. So contact our eco-solvent printing team today to begin your sustainable graphics journey.